Thread tension is a critical factor in achieving high-quality embroidery results. Proper thread tension ensures that stitches are balanced, preventing issues such as thread breaks, loops, or puckering. However, determining the ideal thread tension for an embroidery machine can be challenging. In this article, we’ll explore the importance of thread tension in embroidery, discuss factors affecting thread tension, and provide tips for achieving optimal tension, all while incorporating the use of digitizing services and embroidery file format converters.

Understanding Thread Tension in Embroidery

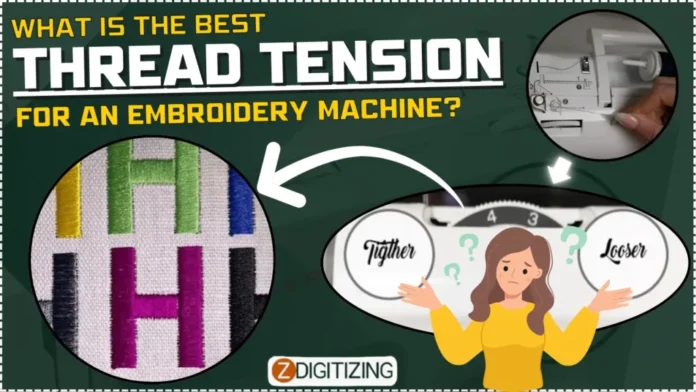

Thread tension refers to the amount of resistance applied to the thread as it passes through the needle and bobbin during stitching. Balancing thread tension is crucial for achieving uniform and consistent stitches, regardless of the fabric type or design complexity. Improper thread tension can result in distorted or uneven stitches, affecting the overall quality of the embroidery.

Factors Affecting Thread Tension

Several factors can influence thread tension in an embroidery machine:

- Thread Type and Quality: Different thread types (e.g., polyester, rayon, metallic) may require adjustments in tension settings. Additionally, using high-quality threads reduces the risk of thread breaks and ensures smoother stitching.

- Fabric Type and Thickness: Thicker fabrics require looser tension settings to accommodate the bulkiness of the material, while thinner fabrics may require tighter tension to prevent puckering or distortion.

- Machine Settings: Each embroidery machine has its unique tension adjustment mechanism. Familiarize yourself with your machine’s tension settings and make gradual adjustments as needed.

Tips for Achieving Optimal Thread Tension

- Start with the Default Setting: Begin with the manufacturer’s recommended tension setting for the selected thread and fabric combination.

- Test on Scrap Fabric: Before embroidering your final design, test the thread tension on a scrap piece of fabric. Adjust the tension settings gradually until you achieve balanced stitches with no visible loops or puckering.

- Check Both Sides of the Fabric: Inspect both the top and bottom sides of the fabric after stitching. Balanced tension results in stitches that appear the same on both sides of the fabric.

- Make Incremental Adjustments: Avoid making drastic changes to the tension settings. Instead, make small adjustments and test the stitches again until you achieve the desired results.

- Consult with Professionals: If you encounter persistent tension issues, consider seeking advice from professionals, such as providers. They can offer insights into optimizing tension settings based on the specific requirements of your design.

Conclusion

Achieving the best thread tension for an embroidery machine is essential for producing high-quality embroidered designs. By understanding the factors affecting thread tension and following the tips outlined in this article, embroiderers can effectively balance thread tension for optimal stitching results. Additionally, leveraging the expertise of digitizing services providers and utilizing advanced embroidery file format converter can further enhance the overall embroidery experience.