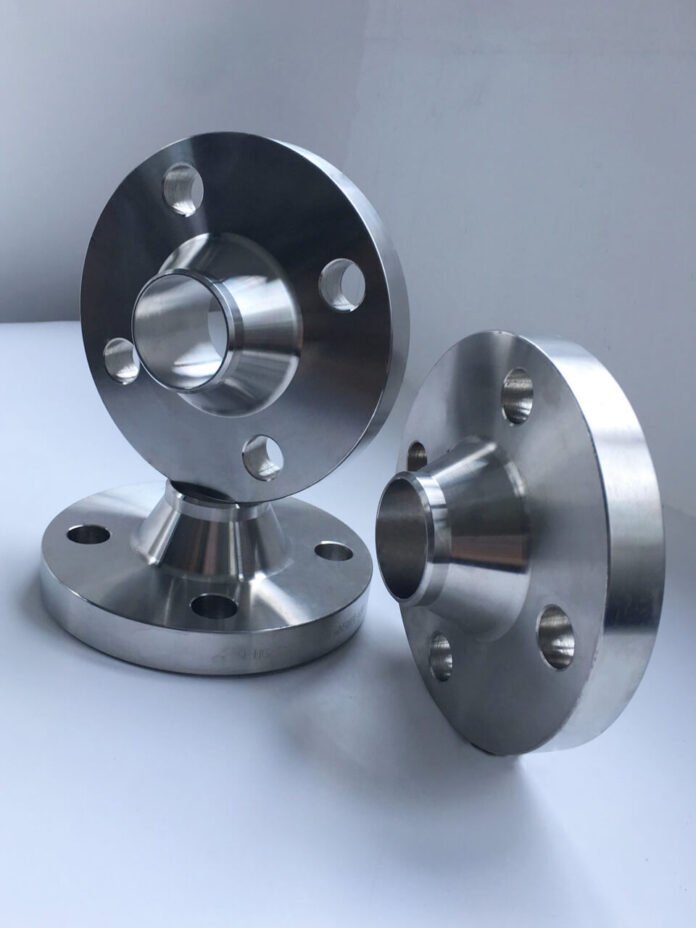

A flange is a cast ring that connects pieces of pipe or other equipment that needs a connecting link. Because there are so many different types of flanges, it’s important to remember their sizes, shapes, dimensions, and diameters.

To begin with, it is important to record the pipe diameters to which the flanges will be attached. Selecting the proper flanges would also be aided by knowing whether the pipes are seamless, welded, ERW, and so forth. Stainless Steel Flange, discs, and rings that attach to pipes to increase support or tensile strength. Frequently, they are welded or screwed to the pipe end. These pipe flanges can be changed by the manufacturer to meet the criteria.

The choice of stainless steel flanges should be based on the needs of the client as there are several grades available. Some of the things are both pricey and highly durable. Both stainless steel 304L and 316L flanges have a high alloy content of about 95% and are made of iron. The stainless steel grades 304 and 316 are chromium-nickel alloys that are robust, withstand most chemicals, and have greater resistance to many types of deterioration.

Various Types of Stainless Steel Flanges

- Stainless Steel Weld Neck Flanges: When the fluid being conveyed by the piping system must flow freely under conditions of high pressure and varying high and low temperatures, welded neck flanges are used.

- Flanges for Stainless Steel Lap Joints: An instance of a slip-on flange. Helps with pipeline maintenance for low alloy steel and carbon. These flanges resemble slip-on flanges in appearance, however, they can be differentiated by the rounded internal flange face edge.

- SS Socket-Weld Flanges: Usage with a smaller diameter and higher pressure, like steam lines. Internal welds guarantee durability. A satisfactory flow connection is achieved because the pipe’s bore and the flange’s bore are the same.

- Slip-on Stainless Steel Flanges: The bore size of a slip-on flange is larger than the outside diameter of the connected pipe because the pipe must move within the flange in order to be joined by a fillet weld. Used in low-pressure conditions. This style is favored over a weld neck in situations when cost or space are restrictions.

- SS Blind Flanges: Suitable for plumbing systems that require routine inspection. Coping with intense pressure brought on by both internal pressure and the liquid’s pressure as it flows through the pipe. With this substance, valves, pipes, and other structures are “blanked out.”

- Stainless Steel Orifice Flanges: To permit access to a line so that liquids or gases can be measured. All standard sizes and ranges are covered by the SS orifice flanges range, which is shared by all flange materials.