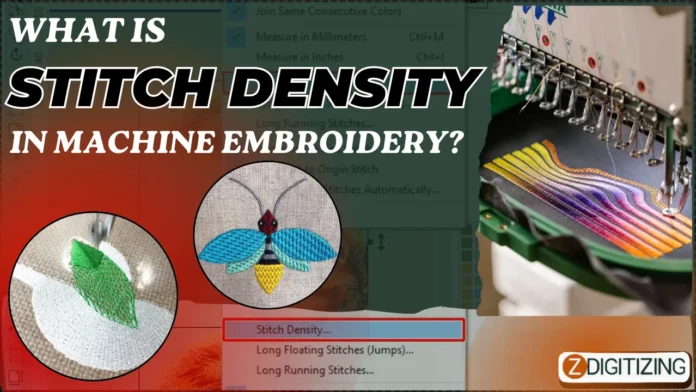

In the world of machine embroidery, stitch density plays a pivotal role in determining the quality and appearance of the final product. Whether you’re a seasoned embroiderer or just starting out, understanding the concept of stitch density is crucial for achieving professional results. In this article, we delve deep into what stitch density entails, its significance in embroidery, and how it influences the digitizing process.

What is Stitch Density?

Stitch density refers to the number of stitches per unit of area in a design. It essentially measures how closely packed together the stitches are within a specific space. This parameter is typically expressed as stitches per inch (SPI) or stitches per centimeter (SPC), depending on the measurement system used.

Importance of Stitch Density in Machine Embroidery

Achieving the optimal stitch density is paramount for ensuring the quality, durability, and visual appeal of embroidered designs. Here’s why stitch density matters:

1. Visual Impact:

The density of stitches directly impacts the appearance of the embroidered design. Proper stitch density results in crisp, well-defined details, while insufficient density may lead to gaps or distortion in the design.

2. Fabric Compatibility:

Different fabrics require varying levels of stitch density to achieve optimal results. While denser fabrics like denim can accommodate higher stitch densities, delicate fabrics may require lower densities to prevent puckering or distortion.

3. Durability:

Adequate stitch density enhances the durability of embroidered designs by securing the threads firmly to the fabric. Insufficient density may result in loose threads or fraying over time, compromising the longevity of the embroidery.

Factors Influencing Stitch Density

Several factors influence the stitch density in machine embroidery:

1. Design Complexity:

Intricate designs with numerous details typically require higher stitch densities to maintain clarity and precision.

2. Thread Type and Weight:

The type and weight of the thread used significantly impact stitch density. Thicker threads may necessitate lower densities to prevent overcrowding, while finer threads may require higher densities for adequate coverage.

3. Fabric Type and Thickness:

The type and thickness of the fabric being embroidered play a crucial role in determining the appropriate stitch density. Thicker fabrics can accommodate denser stitches, whereas thin, delicate fabrics may require lower densities to prevent damage.

Digitizing Embroidery Service: Optimizing Stitch Density for Quality Results

When availing of digitizing embroidery service, it’s essential to communicate your requirements clearly to ensure optimal stitch density. Experienced digitizers understand the nuances of stitch density and can adjust the design accordingly to achieve the desired outcome.

Online Embroidery Digitizing: Harnessing Technology for Precision

With the advent of services, digitizers can now cater to a global clientele with ease. These platforms utilize advanced software and techniques to digitize designs accurately, including optimizing stitch density for superior results.

Conclusion: Mastering Stitch Density for Exceptional Embroidery

In summary, stitch density plays a pivotal role in machine embroidery, influencing the visual appeal, durability, and overall quality of the final product. By understanding the factors that affect stitch density and leveraging digitizing embroidery services effectively, embroiderers can elevate their craft and create stunning designs that stand the test of time.

FAQs (Frequently Asked Questions)

1. What is the ideal stitch density for machine embroidery?

The ideal stitch density varies depending on factors such as design complexity, fabric type, and thread weight. Generally, a stitch density of 5-7 stitches per millimeter (or 12-18 stitches per inch) is considered standard for most embroidery projects.

2. How does stitch density affect embroidery pricing?

Stitch density can influence the pricing of embroidery services, as designs with higher stitch counts typically require more time and resources to digitize and embroider. However, pricing structures may vary among digitizing companies, so it’s advisable to request quotes based on your specific requirements.

3. Can stitch density be adjusted after the design is digitized?

Yes, stitch density can be adjusted during the digitizing process to achieve the desired results. Experienced digitizers have the expertise to optimize stitch density based on factors such as fabric type, design complexity, and desired aesthetic.

4. Are there any limitations to increasing stitch density?

While increasing stitch density can enhance the visual appeal and durability of embroidery, there are limitations to consider. Excessively high stitch densities may lead to thread breakage, fabric puckering, or distortion of the design, especially on delicate or stretchy fabrics.

5. How can I ensure the best stitch density for my embroidery project?

To ensure the best stitch density for your embroidery project, collaborate closely with your digitizing service provider and provide detailed specifications regarding fabric type, design complexity, and desired aesthetic. Clear communication and collaboration are key to achieving optimal results.